Undergraduate senior projects are part of the core program of the department, and Kaplan’s group offers new topics each year (updated July 2025). The currently available projects are listed below. If you are interested, please contact Prof. Kaplan by e-mail.

===================================

The Influence of Nitrogen on Sintering and Grain Growth in Alumina

It is the hypothesis of this study that nitrogen adsorbs to surfaces of alumina (α-Al2O3), reducing the surface energy and thus reducing the driving force for densification during sintering. In a similar manner, nitrogen adsorption may affect the mobility of grain boundaries, thus influencing the kinetics of grain growth.

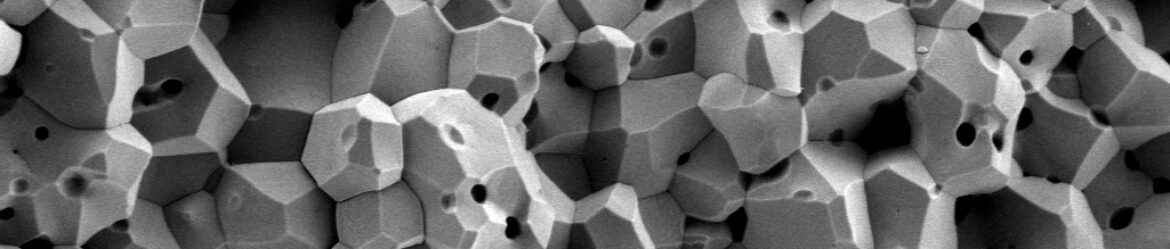

The project will have two experimental parts. In the first, the students will learn to prepare their own alumina compacts using powder processing technology. Sintering will be conducted in nitrogen, and the density as a function of annealing time will be compared to samples sintered in helium and in air. In the second part, fully sintered alumina samples will be annealed in nitrogen or in helium, and the grain size as a function of annealing time measured from SEM micrographs, and the grain boundary mobility will be determined.

===================================

Equilibrium Crystal Shape of Mg-Doped Alumina

Dopants will segregate to surfaces if they lower the surface energy. The changes in relative surface energies change the equilibrium crystal shape (ECS) of a material. Knowledge of the ECS is important for microstructure design. In this project a new approach will be used to measure the ECS. Mg-doped alumina (slip casting with Mg Nitrate or pressing ready to press pre-doped powders) will be prepared. Sinter to full density in air, 1600°C. Prepare small holes at the surface using FIB. Anneal in air to equilibrate the small holes. Cross-section the holes, and measure from the cross-section the angles between planes to identify planes, where the surface normal is measured from EBSD. Measure from the cross-section the relative lengths of the different surfaces and determined the relative surface energies. Build the ECS of Mg doped alumina using Krystalshaper software.

===================================

Equilibrium Crystal Shape of ZrC

ZrC as a high temperature ceramic can be sintered at 2400°C using rapid heating and appropriate doping. ZrC has a rock salt crystal structure. Simulations about the ECS of ZrC exist in the literature, but no experimental measurements are available. The project goal is to experimentally measure the ECS of ZrC. This will require the preparation of ZrC green bodies and sintering to full density in at 2400°C. Prepare small holes at the surface using FIB. Anneal in our special high temperature furnace to equilibrate the small holes. Cross section the holes, measure from the cross section the angles between planes to identify planes. Measure from the cross section the relative lengths of the different surfaces and calculate the relative surface energies. Build the ECS of ZrC using Krystalshaper software.

===================================

Solubility Limit of Y and La in Alumina

It is known that key dopants and impurities in alumina can significantly influence the densification process during sintering, or grain growth kinetics. However, the high temperature solubility limits of dopants in alumina have rarely been quantitatively determined. The goal of this project is to experimentally measure the solubility limit of La and Y in alumina as a function of temperature. Alumina doped with Y and La will be prepared by salt infiltration (or powder mixing). Sinter to full density. Verify from XRD that it is a two phase system, i.e. it is clearly over the solubility limit so that the alumina grains are saturated with the dopant. Verify by WDS a homogenous dopant concentration. Anneal in air at different temperatures (1600°C, 1500°C and 1400°C) and water quench, and furnace-cool one specimen. Prepare samples for WDS and measure dopant concentration by WDS. Determine solubility limit as a function of temperature, and then relevant thermodynamic parameters. Determine the lattice parameters of the doped versus undoped alumina.

===================================

Solubility Limit of Mg in Alumina as a Function of Temperature and Atmosphere

It is known that key dopants and impurities in alumina can significantly influence the densification process during sintering, or grain growth kinetics. However, the high temperature solubility limits of dopants in alumina have rarely been quantitatively determined. Mg is probably the most important dopant for alumina, and while its solubility limit at 1600°C has been determined, the solubility limit as a function of temperature is unknown. The goal of this project is to experimentally measure the solubility limit of Mg in alumina as a function of temperature in air and in a reducing atmosphere (CO2/CO). Mg doped alumina will be prepared via salt infiltration (or pressing pre-doped ready to press powders). Sinter to full density. Verify by XRD that it is a two phase system. Verify by WDS a homogenous dopant concentration. Anneal in air at different temperatures (1600°C, 1500°C and 1400°C) and water quench. One sample to be furnace-cooled. Anneal in our newly constructed rapid heating/cooling furnace and cool at highest cooling rate. Prepare samples for WDS and measure dopant concentration by WDS. Calculate solubility limit as a function of temperature and furnace atmosphere. (For the samples annealed and quenched in the new furnace, we have to take into account that carbon dissolves in alumina as an anion). Determine the lattice parameters of the doped versus undoped alumina.

===================================

Solubility Limit of Ti in Alumina as a Function of Temperature

It is known that key dopants and impurities in alumina can significantly influence the densification process during sintering, or grain growth kinetics. However, the high temperature solubility limits of dopants in alumina have rarely been quantitatively determined. Ti is of interest, since it is known to reduce the temperature required for sintering to full density. The goal of this project is to experimentally measure the solubility limit of Ti in alumina as a function of temperature in air. Ti doped alumina will be prepared via powder mixing. Sinter to full density. Verify using XRD that it is a two phase system. Verify by WDS a homogenous dopant concentration. Anneal air at different temperatures (1600°C, 1500°C and 1400°C) and water quench. One sample will be furnace-cooled. Prepare samples for WDS and measure dopant concentration by WDS. Determined the solubility limit as a function of temperature and extract relevant thermodynamic parameters. Determine the lattice parameters of the doped versus undoped alumina.

===================================

Solubility Limit of Si in Alumina- Influence of Atmosphere and Co-Doping

It is known that key dopants and impurities in alumina can significantly influence the densification process during sintering, or grain growth kinetics. However, the high temperature solubility limits of dopants in alumina have rarely been quantitatively determined. The goal of this project is to experimentally determine the solubility limit of Si in alumina in a reducing atmosphere (graphite element furnace) and co-doped with Mg. Samples will be prepared by pressing undoped and Mg-doped alumina powders, and preparing Si and Si+Mg (co-) doped material via infiltration of alumina preforms with TEOS. Sinter to full density. Verify using XRD that it is a two phase system. Verify by WDS a homogenous dopant concentration. Anneal air at different temperatures (1600°C, 1500°C and 1400°C) and water quench. One set of samples will be furnace-cooled. Anneal in graphite furnace and cool at highest cooling rate. Prepare samples for WDS and measure dopant concentration by WDS. Determine the solubility limit as a function of temperature, furnace atmosphere, and co-doping. Determine the lattice parameters of the doped versus undoped alumina.

===================================

Modeling Spray-Drying for Ceramic Processes

Spray-drying is a common method to produce deflocculated ceramic powders containing a binder for subsequent powder pressing, and then sintering. During this process a stable colloidal suspension of the particles in a liquid matrix (containing the binder) are atomized, and the droplets dry as a function of drop-distance in a small drop-tower. In this project SEM will be used to characterize alumina spray-dried powders as a function of drop-distance in a laboratory-level spray dryer, followed by pressing, sintering, and microstructural characterization of the sintered material. A small drop-tower will be constructed using a Perspex tube with collection plates at various distances in the tube. Alumina slurries will be prepared using conventional slurry preparation including deflocculants and binders, and atomized into the tube. SEM will be used to characterize the powders as a function distance in the tube, and optimized powders (distance) will be collected, pressed, sintered, and characterized (density, grain size).

===================================

Diffusion Bonding of Alumina with Thin Deposited Al Layer

Joining sintered ceramics is a common engineering need, normally accomplished by high temperature brazing processes. However, the temperature of use of the part is then limited by the high temperature properties of the braze alloy (which is usually less than the ceramic parts). Transient phase bonding is an approach where the braze alloy (which in some cases never reaches a liquid state) is dissolved in the two pieces to be joined, resulting in a join which can operate at high temperatures. The project goal will be to utilize oxidation of Al films at the interface between alumina pieces, and subsequent grain growth, to form a high temperature join. The kinetics of the process will be varied by doping the Al with Ga. Thin film deposition of Al and Al(Ga) on sintered alumina pieces, using alumina sintered from ready to press powders. Joining will be conducted in air, at 600C (below Tm for pure Al, and above Tm for Ga doped Al). SEM will be used to characterize the residual Al, crystallization, and grain growth at the join. Final joins between pre-cut alumina bars will be used to measure the fracture strength of the join, compared to monolithic alumina.

===================================

Surface Modification During TEM Sample Preparation

The goal of this project is to understand the surface roughness due to the various stages of TEM specimen preparation. TEM specimens will be prepared from aluminum and alumina, using mechanical polishing and ion milling. The surface morphology will then be characterized using combined AFM and SEM, to understand the influence of various stages of the TEM specimen preparation methods on the microstructure of the surface.

===================================

Y doped ZrC

ZrC is a promising material to be used for high temperatures applications. One of the main challenges of ZrC is oxidation at high temperatures, where ZrC transforms to ZrO2. Y can be added to ZrO2 to stabilize the cubic phase of ZrO2 (thus improving its mechanical properties). The concept of this project is to prepare Y doped ZrC and then perform oxidation experiments in air to evaluate if the ZrO2 formed during oxidation is Y-stabilized ZrO2. In addition, the solubility limit of Y in ZrC will be determined. Processing includes powder mixing, sintering in a new high temperature graphite furnace (Amos), oxidation of ZrC in an air furnace at high temperature (1600C), and characterization of the oxidized phase (thickness, composition) using XRD and SEM. WDS for solubility limit.

===================================

Wetting of Zr on ZrC

ZrC has potential for high temperature applications, but joining of ZrC parts is often required for technological applications. In this project, the use of Zr as a high temperature braze material and the potential to convert the Zr to a transient braze after carburization will be evaluated. The project goal is to measure the relative interface energy (wetting) of Zr (liquid and solid) on ZrC. This Zr films will be deposited on ZrC substrates. Thermal annealing will be conducted in a carbon furnace to form small droplets of Zr above the melting point, and similar experiments for solid-state dewetting below the melting point. FIB will be used to cross-section the Zr, and to determine contact angles (for experiments above Tm) and for Winterbottom analysis after annealing below Tm, from which the wetting will be determined.

===================================

The Influence of Crystallographic Anisotropy on Surface Diffusion

A measure of surface diffusion is important for many processes, and is critical for sintering to full density where the influence of segregating dopants on pore mobility is via alteration of surface diffusion. Surface diffusion coefficients can be estimated by measuring the relative rate by which perturbated surfaces flatten as a function of time and temperature. The goal of this project is to measure the difference in relative surface diffusion of a liquid versus a solid. For this project, grooves will be etched into the surface of glass and quartz using Xenon FIB. The evolution of the grooves (specifically their amplitude) as a function of time at a defined temperature will be measured by cross-section FIB.

===================================

3D Printing Alumina with Al

A large amount of binder is used in the common 3D printing techniques for ceramics. This poses a real problem for subsequent sintering of ceramic parts. The idea is to utilize a metal as a binder, which will oxidize during sintering. Specifically in this project, we will mix alumina powder with Al (or other metals) so that the metals act as “binder” during the printing process under a laser beam. The goal of the project is to print test parts made of alumina powder with varying content of Al powder, and to characterize the printed and sintered material. Powder samples of Al-alumina will be prepared by simple mixing, at various Al contents. The powders will be used for 3D printing of test samples using a laser printer. SEM analysis will be used to evaluate the depth of interaction of the laser beam by determining to which depth the Al was melted. Annealing will then be used to oxidize the Al, and sinter, and the density will be evaluated.

===================================

Phase Detection limit of XRD

The detection limit for quantitative phase content analysis in XRD is usually not measured and not presented in the literature. The goal is to develop a method to easily identify the detection limit by analyzing the XRD peak shape and intensity, using standards prepared by mixed powders of known composition. For this project, Ni and alumina powders will be mixed at known phase concentrations. XRD patterns will be acquired, and the peak shape of the reflections as a function of scattering angle will be determined using full spectrum line profile fitting (Rietveld). The peak shape and measured background values will be used to convert the background values to relative phase concentrations for determination of the detection limit at a defined confidence level.

===================================

ZAF calculation in Python and Testing Results on a Known Standard, Calculation of layer Thickness Using EDS

ZAF is the common approach to quantitative EDS analysis in SEM. The ZAF solution requires a numerical solution, and analysis of various material constants related to inelastic scattering, absorption, and florescence. All SEM-EDS system are black-box approaches where the exact parameters used for analysis are not defined, and this is further compounded for approaches based on simulated k-factors. The goal of this project is to develop a simple ZAF code for quantitative EDS analysis. EDS data will be collected from standards available in our center, and error of the code will be evaluated using the standards. The results will be compared to those from another project developing code utilizing the so called Phi-Rho-Z (Φ(ρz)) approach.

===================================

Phi-Rho-Z (Φ(ρz)) calculation in Python and testing Results on a Known Standard, Calculation of layer Thickness Using EDS

The Phi-Rho-Z (Φ(ρz)) method is a matrix correction technique used in electron probe microanalysis (EPMA) and energy-dispersive X-ray spectroscopy (EDS) to obtain accurate quantitative analysis of specimens. It is a more advanced alternative to the traditional ZAF correction method, particularly effective for light element analysis and situations where X-ray absorption is significant. The solution requires a numerical solution, and analysis of various material constants related to inelastic scattering, absorption, and florescence. All SEM-EDS systems are black-box approaches where the exact parameters used for analysis are not defined, and this is further compounded for approaches based on simulated k-factors. The goal of this project is to develop a Phi-Rho-Z (Φ(ρz)) code for quantitative EDS analysis. EDS data will be collected from standards available in our center, and error of the code will be evaluated using the standards. The results will be compared to those from another project developing code utilizing the so called ZAF approach.

===================================