Open topics currently exist in Kaplan’s group for MSc and PhD students. Below is a brief description of each open topic. If you are interested in receiving more information, please contact Prof. Kaplan by e-mail or by telephone (04-829-4580).

The Influence of Fe on Grain Growth of Al2O3

Advisor: WD Kaplan

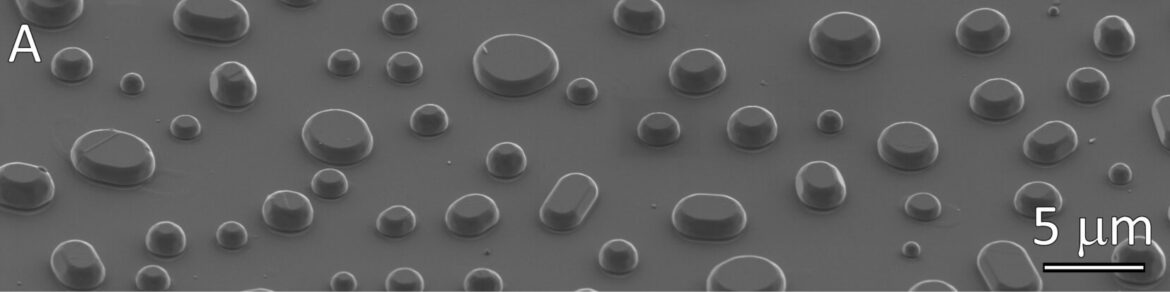

An important microstructural feature of polycrystalline materials is grain size, since grain size and the respective area of grain boundaries affect mechanical and functional properties. As such, grain growth plays a significant role in microstructural evolution during sintering of polycrystalline materials. One of the most studied ceramic materials is a-alumina (a-Al2O3), which has served as a paradigm for the study of grain growth and is important for technological applications. Grain growth kinetics in alumina have been extensively studied, where major efforts have been made to understand the influence of key dopants and impurities on the average grain boundary mobility, and the effect of exaggerated grain growth.

While extensive measurements of grain growth have been conducted for alumina, it is only recently that the high temperature solubility limit of key dopants and impurities have been measured (by WDS). Mg, Ca, and Si have extremely low solubility limits at 1600°C (132 ppm, 51 ppm, and 188 ppm, respectively). Since these values are below the detection limits of most techniques used in the past, it is not clear if the grain boundary mobility measurements conducted on alumina were in the single phase region, or were influenced by particle drag (or a liquid phase) due to second phase precipitation.

Furthermore, recent studies of Ca doped alumina have now shown that even at dopant levels below the solubility limit, Ca causes a significant increase of grain boundary mobility. Thus, the accepted explanation that dopants such as Ca and Si cause liquid phase formation leading to rapid grain growth, are not complete. The actual mechanism by which dopants increase grain boundary mobility can only be speculated, and the goal of this research program is to address this important question.

The fundamental objective of this proposed research program is to quantitatively understand the influence of segregating Fe on the mobility of grain boundaries, at dopant levels below the solubility limit (~8 at.%). The outcome of this research will have fundamental contributions in the following manner:

- It will confirm existing theory regarding possible first-order interface transitions, within an experimental framework which provides fully defined relevant thermodynamic parameters. Dopant concentrations which show a discontinuous change in grain boundary mobility will serve to identify first order transitions in the state of grain boundaries.

- It will provide experimental evidence for the mechanism of grain boundary motion in alumina, and how dopant species affect the mechanism.

- It will elaborate the nature of dopant affected space charges at grain boundaries in alumina, and the possible influence of space charge on mobility.

- It will explore the influence of co-doping on grain boundary mobility, without the influence of secondary phases.

Induction Sintering of Al2O3

Advisor: WD Kaplan

Densification during sintering is always achieved by thermal activation. One of the challenges of homogenous heating, so as to minimize stresses during densification. These stresses can be significant, and limit the sintering rates of ceramics.

The concept to be explored in this project is thermal activation of non-conducting ceramics (alumina) by inductive heating of nanometer-sized particles of a secondary (conducting) phase distributed in the pre-sintered compact. Secondary phases to be tested include graphite, Ni, and W.

The density as a function of induction furnace conditions will be explored, and the general microstructure of the sintered bodies will be characterized using XRD, SEM, and TEM. The wear resistance of sintered samples will be measured.